The Latest

3 Ways AGVs Will Improve Your Warehouse Efficiency

Automated guided vehicles (AGVs) are not a recent phenomenon. In fact, automation technology has been used in the manufacturing industry for decades in assembly lines. This technology hasn’t been mainstream with material handling equipment like forklifts and tow tractors; however, equipment manufacturers are now producing automated forklifts that can increase your uptime, profits and overall warehouse efficiency.

Even though the upfront cost of an AGV is higher than traditional manual equipment, the more that businesses see the major savings in the total cost of ownership offered by automation technology, such as labor, fuel and repairs, the more normalized it will become.

1. What automation means for your budget

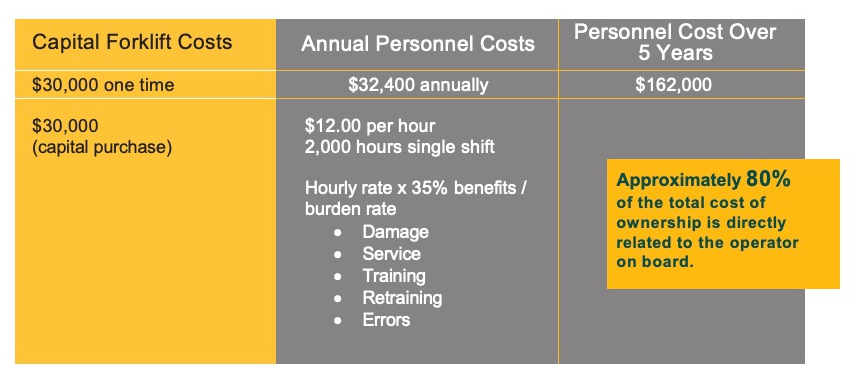

Automation technology may seem like a more costly investment when choosing between AGVs and a manual truck; however, when the costs are broken down, the total cost of ownership of a manual truck is much higher than an AGV.

Infographic from MCFA

What many people may not realize is the cost of ownership of a manual truck includes personnel costs, which consists of an hourly wage, preventable damage, service, training, retraining and errors.

While having a core team of highly-trained forklift operators to help maintain the warehouse is essential to the success of your operations, incorporating more automation technology into your warehouse will keep your overall costs much lower over time.

The day-to-day functions of your warehouse can be completed by the calculated and repetitive movements that are programmed into your automated guided vehicles.

2. What automation technology means for your warehouse

AGVs integrate seamlessly with your team and current manual truck fleet. And with built-in laser navigation, you don’t have to change anything about your existing warehouse design. With an AGV in your warehouse operations, your business will be ahead of the curve as automated technology becomes more normalized in material handling. You’ll also be saving on costs throughout the lifespan of the equipment.

Jungheinrich, a manufacturer with decades of electric lift truck expertise, offers two truck categories for AGVs: the tow tractor and the automated stacker. Both trucks offer precise navigation technology to maneuver effortlessly through your warehouse and move your product. Visit our video library to see these AGVs in action.

3. What AGVs mean for your team

A concern for many businesses is losing valuable team members to automation technology. While this is a valid concern, and AGVs will impact the number of operators you need in your warehouse, it doesn’t remove the need for manual labor. Jungheinrich’s AGVs are designed to work with your team and elevate your existing resources to create the most efficient warehouse operations possible.

We know how important it is to have a team of individuals to bring ideas, experiences and best practices into the workplace – and automation technology won’t make that go away. It pairs together the ideas of the experts within your business and the efficiency of automated equipment to make your operations more streamlined and more profitable.

If you’re interested in learning more about how you can begin to incorporate automated guided vehicles into your warehouse, contact us today and a Fraza representative will help guide you through that process.